O&G/Subsea - Sensor Testing Pot

Scope

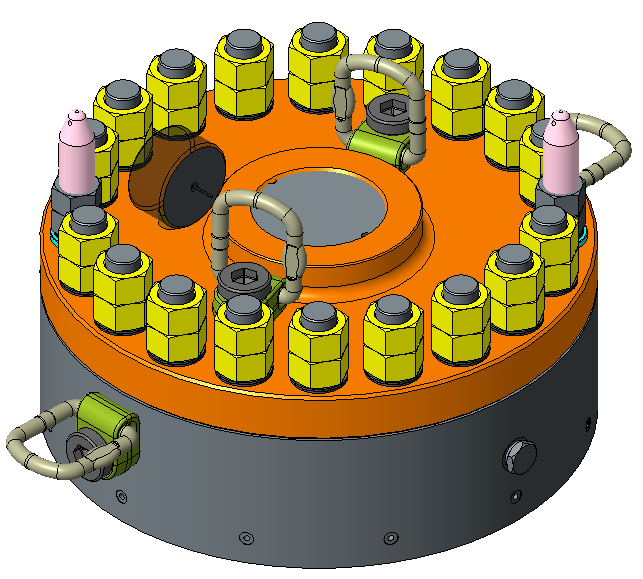

D3 worked with our long-term client to design, develop, manufacture & test a sensor testing pot capable of withstanding 572bar. The pot was to be used to carry out tests at varying pressures on their world-leading sensor technology.

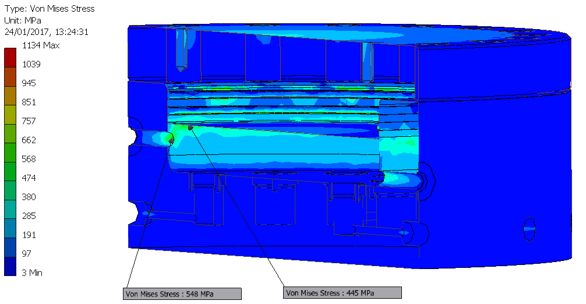

The design pressure of the pot was 400bar, but in line with BS EN 13445 the test pressure of 572bar was required.

Solution

We worked extensively with our client to agree on material specs, required ports for filling & assembly methods.

We successfully produced a suitable 3D design, with required purchased (off the shelf) parts alongside a full documentation package inclusive of drawings, FEA analysis and Calculation report. We then provided the finished hardware, assembled and tested to 572bar.

Summary

D3 successfully provided our client with the design and physical finished product, allowing them to test there sensors up to an operating pressure of 400bar (equiv. 4000m sea depth).

Benefits/Solutions:

Full detailed documentation package including all required models, drawings, calculations and certification reports.

Enable our client to save costs on outsourcing testing of their sensors, by now doing them ‘in-house’ allowing closer monitoring of results.

Safety-oriented design with robust analysis and attention on material selection, calculations and analysis.

Our client has used this extensively to further assist in R&D and performance improvement of their sensors.