Medical Device - 3D Design, Assembly & Prototyping

Scope

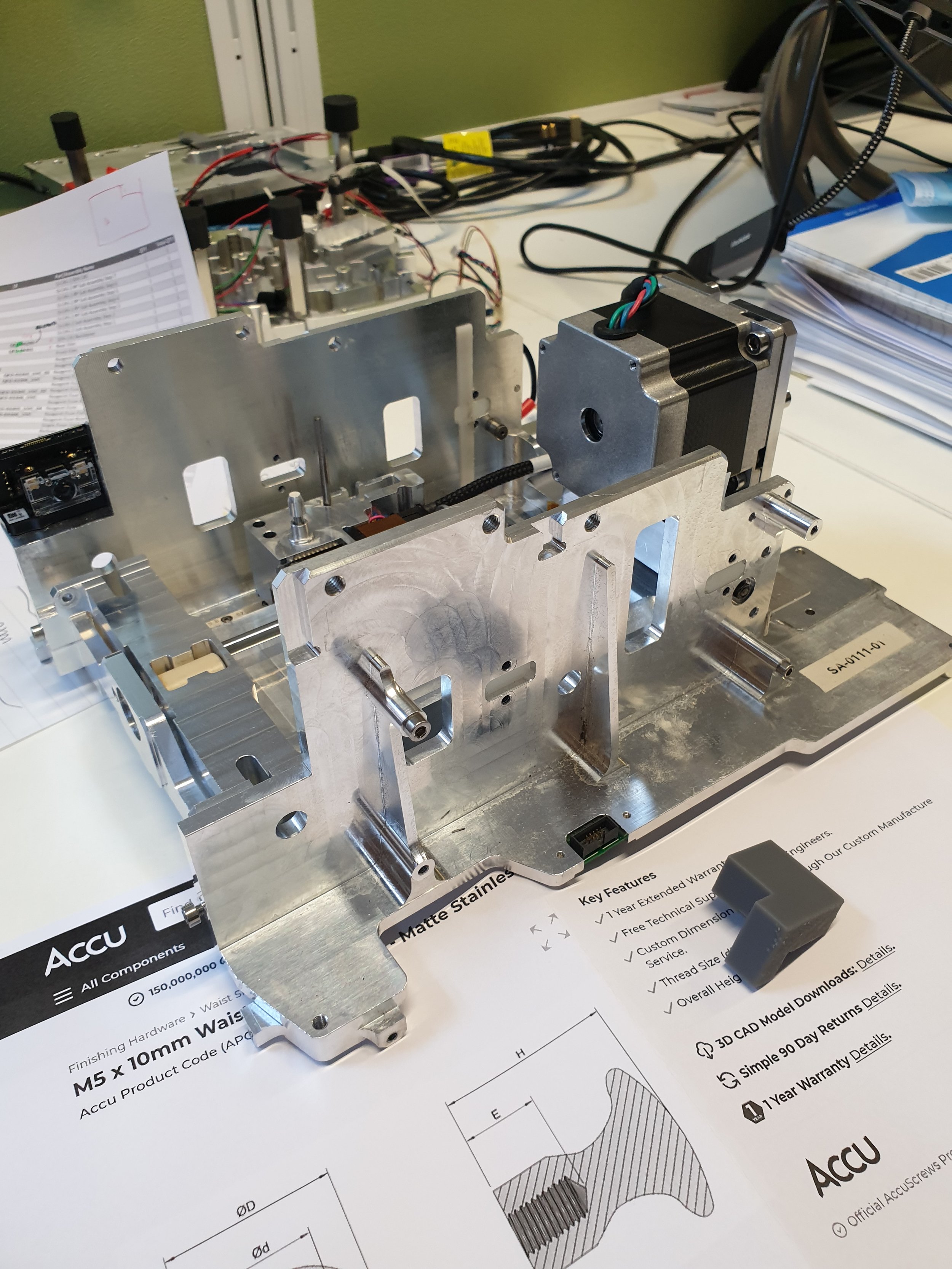

D3 were tasked by our client to review an existing rapid multiplex PCR testing device. D3 were to review the design & drawings, create new ones (where applicable) and ensure the design was refined to allow for mass-manufacture. The design intricacies are patent-protected and will therefore not be shown with too much clarity.

The 3D design and drawings were done within Solidworks.

Solution

On-site meetings were held with our client, where our designers were able to see prototypes of the existing design and get a clearer understanding of the design. From there we worked on optimising the 3D models and drawings to ensure they were as easy to mass-manufacture as possible and also cost-efficient.

Summary

Working with our client and doing prototyping and assembly work helped us to achieve an improved more robust design.

Benefits/Solutions:

Designs simplified where possible to allow for some key high-ticket items to be injection moulded.

High-level detailed drawings provided, making it easier for manufacturers to both understand and physically make.

Prototypes produced and tested before finalising design to achieve long-term savings.

Approx. £1000 cost-saving per device, which was viewed as a huge win for our client.

Providing Engineering Solutions for 25 years

Call us on +44(0)191 4380099

Email @enquiries@d3-uk.com or use the contact form: