Advanced Pipeline (ILI) Tool - Design & Documentation

Scope

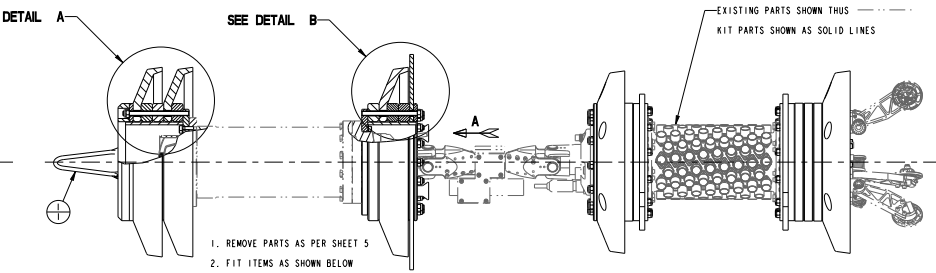

D3 were tasked by our long-term valued client to assess the feasibility of upgrading an existing core inspection tool, to see how it could efficiently be adapted to suit multiple different pipeline diameters.

A focus was put onto cost-efficiency and easy to adapt/assemble for each different size pipeline. PTC Creo was utilised for the 3D modelling and drawings.

Solution

A review into the existing core tool was first undertook, to assess existing parameters and if they would be suitable and easy-adaptable for the problem at hand. After a review, we found that would be able to provide our client with the design and documentation to allow them to adapt the core tool to easily inspect a further 5 different size pipelines. (Core was 16” - with 18,20,22,24 & 26” possible with efficient changes).

Summary

D3 successfully tackled the challenge and provided our client with a great outcome, some of the benefits listed below. 20” variant is shown as an example, to the right.

Benefits/Solutions:

Existing 16” ILI tool was efficiently adapted to allow for a further 5 line-sizes to be inspected.

Huge potential cost-saving provided by utilising existing hardware, keeping that as a core and adapting with some minor changes to provide a further 5 possible options to present to their end clients.

Easy to follow professional documentation package, used to present to their end client and also easy to follow assembly instructions for technicians.

Providing Engineering Solutions for 25 years

Call us on +44(0)191 4380099

Email @enquiries@d3-uk.com or use the contact form: